!!!! Disclaimer !!! Spoiler !!!!

Stop reading if you do not want to know how this trick works.

This Magic trick is performed in Forever Plaid. In this trick the actor takes a razor blade out of a handled shaving razor and sticks it in his mouth acting like he swallowed it. He follows this with 2 more spare blades. Then he takes some floss and cuts a pieces off and pretends to swallow it. Then, after swallowing actions etc, he proceeds to pull out of his "empty" mouth the 3 razor blades all tied together on the floss.

This projects was all done by me start to finish. How to do it was learned by all from a magic DVD. Initially it was thought maybe will only need 8-12 sets. Nope. Eventually ended up making close to 40 sets. (6 blades a set). This prop has to be done very carefully. They are put in an actors mouth, and these are real razor blades. We don't truly want him getting cuts in his mouth.

It starts off with disposable razors blades. These tend to come 10 to a pack and are slightly oiled to prevent them from rusting. Needed to wipe each one off.

Contact paper is what is used to cover the blades and make them safe. A 2"x2" square was cut out for each. The buttons seen below come into play shortly.

Once the individual blade is wrapped in the contact paper, the excess needs to be trimmed off. This has to be done carefully and well. You don't want to cut to the metal and expose a razor edge, and if the angle of the curve cut on the contact paper is too steep, that edge becomes sharp. I needed to make these absolutely safe for the actor.

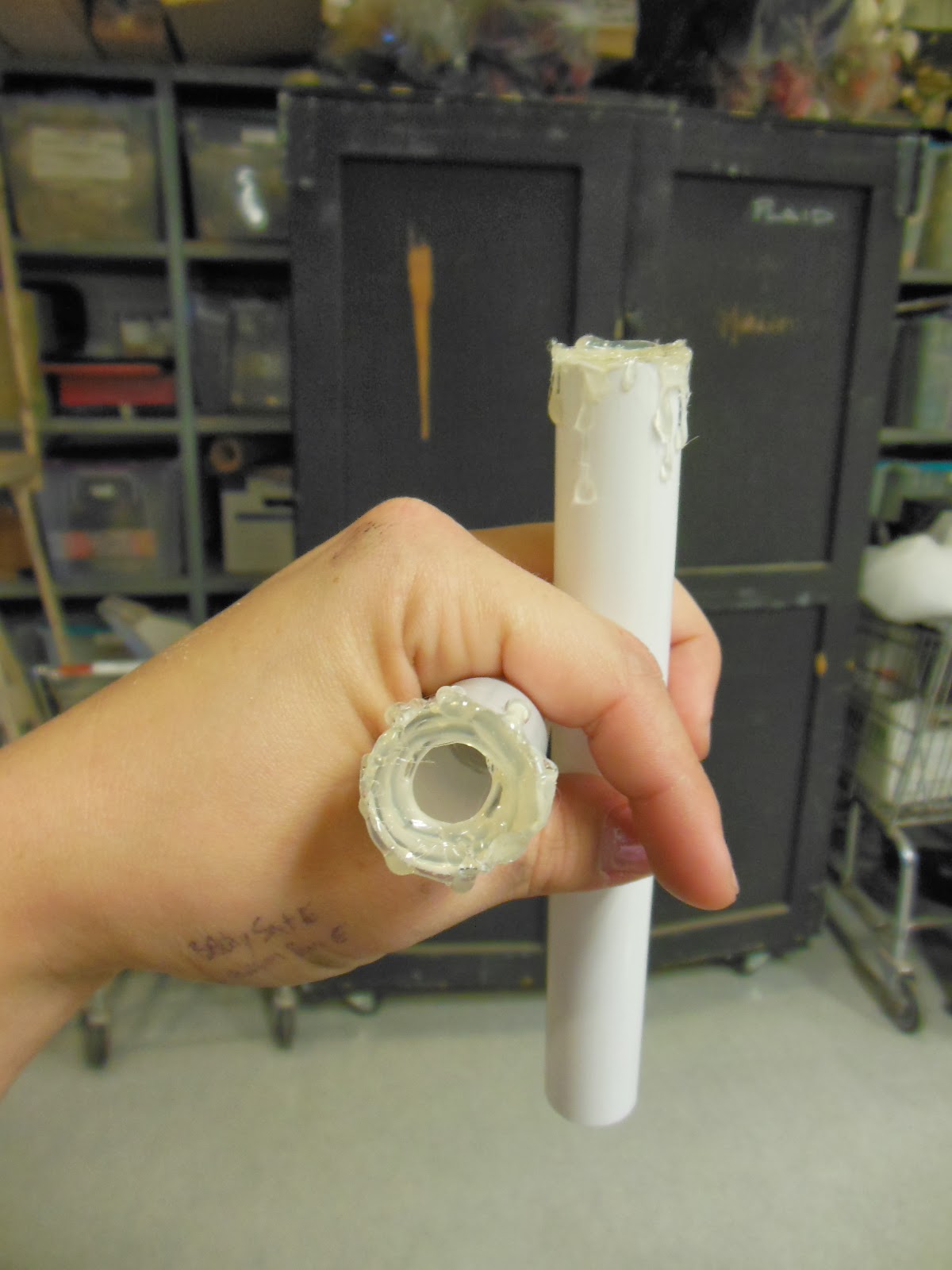

For each set, one of the blades needs the center section of contact paper trimmed out so it will fit in the shaving handle. (Rt side below) Part of the actors action is to remove this blade in front of the audience. It helps define what these are.

He then proceeds to "swallow" it. Followed by 2 more. These get tongued to the inside of his cheek. Next, he takes a length of floss and pretends to swallow that, tonguing it to the side with the newly inserted blades.

In the mean time, he has had a package in his mouth. This has 3 of the razor blades strung along a string. It has a button at one end to make it easy to grab and pull out the rigged blades. These are always strung at a similar distance and on a length of string

Below is a complete set, along with the HyMark thread used to string it, and 2 blades in the contact paper stage.

Initially each set was wrapped as a whole in a zip-lock baggie. After about a week or two of the show running, the actor and run crew asked that the components be separately combined. The strung razors were each wrapped up into a sandwich bag and taped shut, and then put into a 1 gallon zip-lock bag. This keeps them orderly and not tangled with each other. 2 other zip-lock bags were then used. One for the center cut out prepped razors, and one for the singles.